Effective Repairs For Leaking Concrete Swimming Pool

Concrete crack leak sealing injection with high-quality TDI polyurethane* is the best way to stop a leaking concrete pool crack.

This is because the TDI polyurethane is injected deep into the building element forced under high pressure. Once the product is inside the crack, it chases the water present in the crack and begins to foam and expand filling the entire crack. It sets in minutes, forming a dense, durable and flexible seal preventing future water leaks. Water will now remain inside the swimming pool.

Waterstop Solutions specialises in skilled techniques in high-pressure injection with a high-quality TDI polyurethane to the targeted area to form a deep seal and stop water from leaking through the concrete cracks.

Waterstop Solutions utilises the same techniques and products that we have approved for use on major civil structures with a design life of 100 years.

*The TDI polyurethane (hydrophilic) not to be confused with MDI polyurethane (hydrolphobic). The hydrophilic polyurethane provides a considerably higher adhesion and less shrinkage than MDI polyurethanes while still meeting AS4020 (Australian Standard for potable water).

Image: Leaking cracked concrete swimming pool.

Image: Cracked, leaking concrete pool injected with polyurethane creating a waterproof seal.

The concrete swimming pool crack repair was carried out by Waterstop Solutions with high-pressure polyurethane injection. After the leak sealing injection, the injection ports were pulled and plugged. The pool is ready for the next step in surface detailing to be carried out by the pool renovation specialist.

Concrete Pool Leak Sealing / Polyurethane Injection – The Waterstop Solutions Process

Concrete crack leak sealing involves injecting a fully flexible water reactive hydrophilic polyurethane under high pressure.

High-pressure injection of high-quality TDI liquid polyurethane forces the material into leaking cracks, joints, voids and other defects.

We use the highest quality injection product available offering superior performance benefits including:

- Permanent flexibility

- Very low shrinkage

- Water potable, compliant to AS4020 (Australian Standard for potable water)

- Low viscosity

- Hydrophilic reaction (the product is actively chasing moisture, filling and sealing the crack by rapid reaction with the water present in the crack)

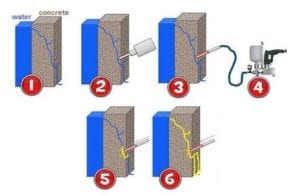

Polyurethane Concrete Crack Injections step by step. Leak sealing injection technique.

- 10 mm holes are drilled typically at 200 mm intervals to intersect the concrete crack or joint.

- We insert high-pressure non-return injection ports into the holes, then the injection process begins pumping the material into place to fill the targeted area.

- The material (Polyurethane) then cures rapidly depending on the amount of moisture present.

- We then remove the injection ports and repair the drill holes. This can be done shortly after the works are completed. However, if the ports are positioned overhead and /or a larger void was found, this process may occur the next day.

- Sometimes we encounter unforeseen voids or building faults, which require additional material. We normally budget in 1kg/Lm. Additional material used will be charged out accordingly.

Where holes are required through tiling, we can as an added service, core-drill 20 mm holes through the tiles prior to drilling the 10 mm holes to help prevent the tiles cracking or chipping. Note that drilling can crack or damage tiles if not removed.

If water is seeping into your property, concrete structure and if you have cracked or damaged concrete, we are happy to arrange a site visit with our experienced inspector for an assessment, our recommendations and quotation to carry out remedial repairs.

Brisbane office: (07) 3205 1899

Email: [email protected]

Sydney office: 02 9346 8308

Email: [email protected]

Good maintenance begins with a proactive approach to maintain, keep, preserve and protect a building.

Remember that seepage/water ingress into areas such as balconies, basements, concrete roofs, car parks and retaining walls, should not be ignored – call a remedial waterproofing professional today for an assessment to provide you with the best solution for your situation.

At Waterstop Solutions, we carry out a wide range of remedial works to concrete structures post construction stage in Brisbane, Gold Coast, Sunshine Coast, Sydney and outlying areas in Queensland and New South Wales .

Equipped with major civil works experience, we can quickly determine the best approach to rectify all seepage and concrete deterioration issues.