The whole system to each concrete and joint repair is performed in less than a day – with minimal downtime

Recently Waterstop Solutions tendered to some significant concrete and joint repairs / refurbishment at one of the biggest Distribution Facilities in Brisbane, Queensland.

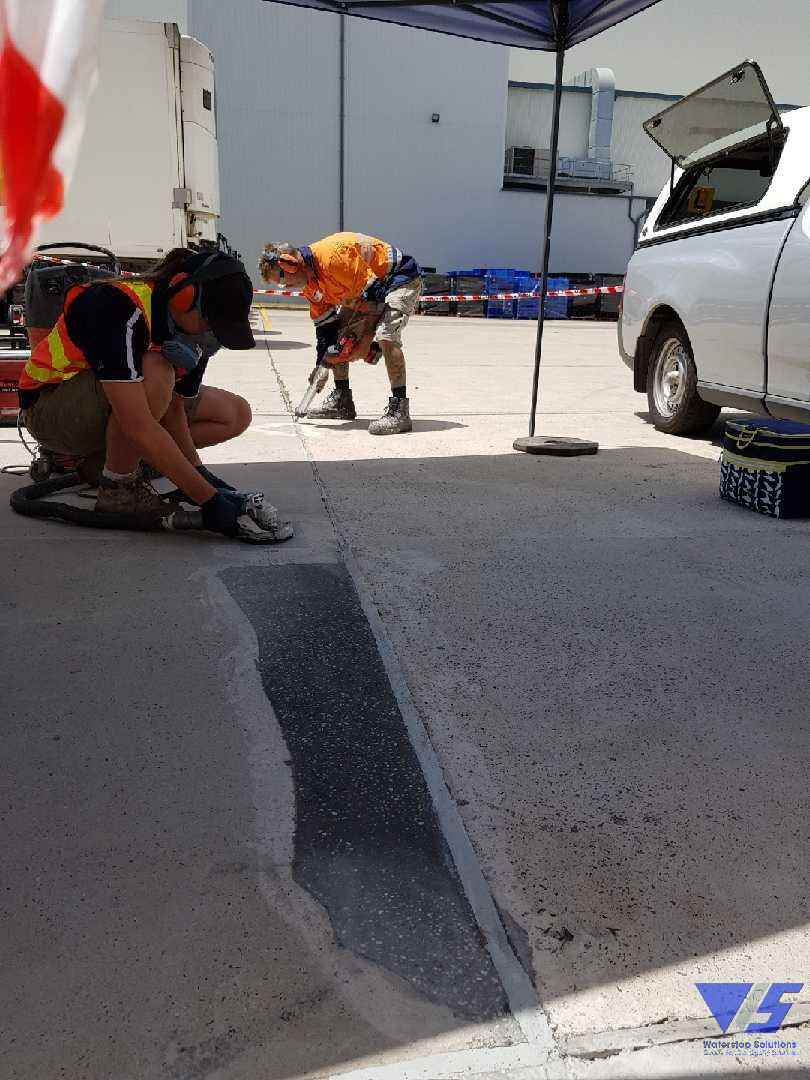

The joints were separating and breaking out leading to significant deterioration and degradation of the concrete surface. However, whilst working around thousands of truck movements in and out of the facility every day, Waterstop Solutions continuously managed to put health and safety of both the site personnel and our own technicians first whilst completing the job in good time.

The whole system to each repair is performed in less than a day with our industrial propriety concrete repair systems.

The compound that we use is a proprietary product that has been developed by Waterstop Solutions during the civil tunnel works previously completed, that included the Airport Link as well as the Clem 7 tunnel in Brisbane, QLD.

The extra benefit our client received with this concrete repair system, was that work could go straight back into full service with minimal downtime, due to the repair systems durable formula that allowed for full traffic and vehicle loading on the same day.

The Benefits of Floor Joint Rehabilitation

• The best surface for safe and efficient movement of goods is a smooth, hard and uninterrupted surface.

• Improved productivity of material handling and traffic efficiency.

• Vehicles can move at speed without slowing down to manoeuvre over separated joints.

• Reduced vehicle and repair costs and downtime due to wheel replacement.

• Time and Cost Effective Solution – If left untreated, the defect grows wider and deeper that eventually will require expensive and time consuming repairs.

• Reduced impact points for hard wheeled traffic.

• Reduced risks of injuries due to load tipping.

• Reduced risk of claims from drivers due to lower back distress cased by jagged movements due to wheels getting caught in gaping and deteriorated floor joints.

Do you have deteriorating concrete joints with separating gaps and broken joint sealing that require concrete repair and joint refurbishment?

Capture 1: Before concrete and joint repair Capture 2: Concrete repair and joint refurbishment by Waterstop Solutions

Have you seen any signs of wet or damp walls and / or floors in your basement, garage, warehouse or storage facility that require remedial waterproofing?

We are happy to arrange a site visit.

Follow this link to Book inspection with our senior waterproofer and concrete expert

Ph: (07) 3205 1899

Email: [email protected]

Click here to view our Capability Statement and Technical Systems Information Sheet to find out what other services we can provide you with.

Waterstop Solutions (Qld) – Trading since 2009.

Speciality – Remedial Waterproofing and other specialist chemical construction product applications generally related to remedial works.

What we are best at – problem solving and designing systems to meet client needs, leak sealing, injection works, joint remediation

Staff – 8 full time experienced Technicians, with certification including EWP, confined space, class III WP, shots for sewerage works, plus several regular casual labour.

Job History – All Brisbane City Road Tunnels, reservoirs, dams, WTP’s, WWTPS, manholes and pipe work, Commercial, Civil, Industrial through to residential.

Waterstop Solutions is committed to providing a high standard of service. With more than 50 years combined industry experience in our management team, we lead our work force to deliver just that. The best measure of our success is the “follow on” works from our existing clients.