17 Jan Waterstop Solutions Capability Statement

Waterstop Solutions Services – Technical Systems Information

Remedial Waterproofing Expertise

Benefit From Major Civil Works Experience

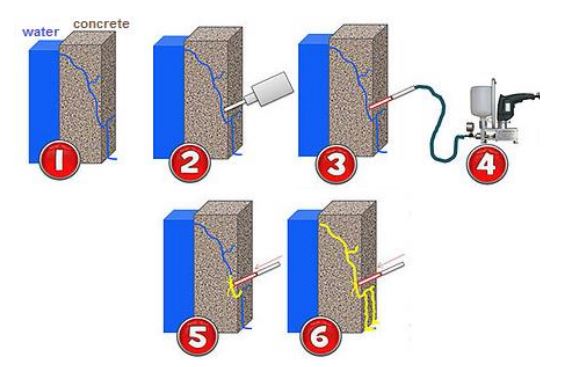

Leak Sealing / Polyurethane Injection / Epoxy Injection / Concrete Crack Injection

- Involves injecting a fully flexible water reactive hydrophilic polyurethane under high pressure.

- We use the best injection product available offering superior performance benefits including

- permanent flexibility

- very low shrinkage

- water potable

- low viscosity and

- hydrophilic reaction

- 10 mm holes are drilled typically at 200 mm intervals to intersect the concrete crack or joint. Where holes are required through tiling, we can as an added service, core-drill 20 mm holes through the tiles prior to drilling the 10 mm holes to help prevent the tiles cracking or chipping.

- Drilling can crack or damage tiles if not removed.

- We insert high-pressure non-return injection ports into the holes, then the injection process begins pumping the material into place to fill the targeted area.

- The material (Polyurethane) then cures rapidly depending on the amount of moisture present.

- We then remove the injection ports and repair the drill holes. This can be done shortly after the works are completed. However, if the ports are positioned overhead and /or a larger void was found, this process may occur the next day.

- Sometimes we encounter unforeseen voids or building faults, which require additional material. We normally budget in 1kg/Lm. Additional material used will be charged out accordingly.

Image: Crack Sealing Injection Ports

Image: Polyurethane concrete crack injections

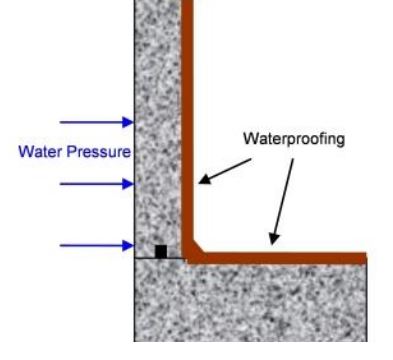

Negative / Reverse Side Waterproofing Membranes

Ideally, waterproofing is installed externally (positive side) against the soil. However, where access to the external wall is limited, we treat internally.

- We must remove any plaster, paint, render, framing etc to access the substrate of the wall.

- The membrane we use is 100% solids active ingredient latex polymer.

- The membrane is breathable, so allows water to pass through it as a vapour.

- One can paint over the waterproofing membrane with breathable paint e.g. low sheen or matt acrylics.

- The membrane is water-based, so any vapours are safe.

- It is critical that no holes or fixings are put through the membrane because this may compromise its performance.

- The waterproofing product is designed to handle up to positive 50-metre water pressure and reverse side 30-metre. This means the tensile strength of the membrane is often stronger than the masonry to which it is applied.

- The substrate cannot have water passing through when applied or curing otherwise the product could be compromised.

- The membrane is flexible so it will handle a small amount of movement.

- The waterproofing product has an applied finish, which can be inconsistent and slightly rough. It is therefore not intended to be decorative or the final finish.

Image: Negative / Reverse side waterproofing membrane, remedial waterproofing.

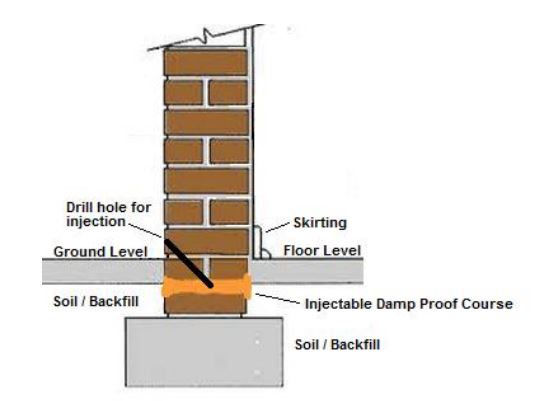

Rising Damp Treatment With Injectable DPC (Damp-Proof Course)

Involves injecting a damp-proof course (DPC) into a location where no physical DPC is present.

- We drill holes at regular intervals. The distance between the holes will vary depending on certain variables such as the type of brick, cavity and how far the product travels when injected.

- The product cures clear/invisible. In some cases, however, it may slightly darken the area where applied. White spirit is used as a carrier so it does have a strong odour which dissipates quickly.

- The product works by lining the pores of the substrate to reduce their size so water can no longer pass through, but air still can. The method work on moving cracks, wide gaps or voids.

Image: Injecting DPC -Damp Proof Course to treat rising damp.

Concrete Repairs

- Concrete Cancer can kill building if not stopped. Concrete cancer is rust – specifically within reinforcing steel.

- The problem is very likely to be much more extensive than what is apparent on the concrete surface. The cancer will have spread along the reinforcing in each direction. It is impossible to know the extent until the concrete is chiselled away.

- The typical method of repair follows a process of:

- saw-cutting the perimeter to eliminate feather edges.

- the concrete around the reinforcing steel is chiselled away.

- a rust inhibitor is applied to the steel.

- after completion of material removal, primers are applied and formwork may be erected to close the cavity prior to installing the repair resin.

- a specialised mortar is used to patch the area.

- cracks can also be repaired using a technique called crack injection where suitable epoxy or polyurethane resins are injected.

- Treatment of concrete cancer should also incorporate proper weather/waterproofing it risks being a temporary solution.

The images below show an example of concrete repair after the first step that is to carry out the Surface Preparation, which is to remove loose and deteriorated concrete.

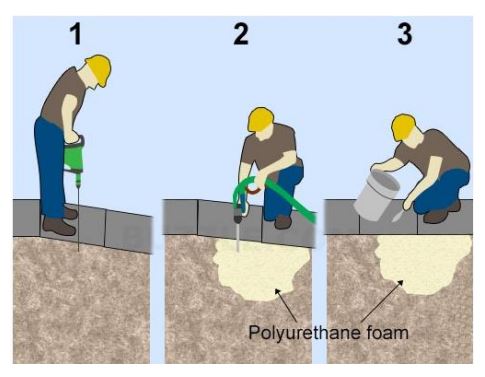

Ground Consolidation and Slab Jacking

- Lifting slabs/structures and improving ground conditions with cutting-edge mining technology.

- The process is fast and light equipment is used. It is relatively non-invasive, leaving minimal footprint.

- We inject moisture reactive urethanes that glue the ground together into a rocky mass. The urethanes self-react to create lift and fill voids.

- The process can be targeted and controlled to reach desired locations.

Grinding

This method is used to remove old coatings and soft renders.

- We use dust extraction technology that captures 99% of the material.

- It is recommended that sensitive items are covered or removed from the area prior to work commencing

Joint Rehabilitation and Joint Sealing

For work requiring re-profiling of joint edges

- Repairs are square-cut to prevent feather-edge cracking and to maximise durability.

- Polymer repairs are used for rapid setting and higher impact resistance.

- Joints are re-cut and re-sealed to protect them from further damage.