20 Nov Wet basement after rain – water seepage repair

Subscribe to our newsletter

Remedial waterproofing to stop water seepage in basement

- Waterproof membrane refurbishment.

- High-pressure leak sealing injection of hydrophilic polyurethane resin into floor/wall joint.

When we have a decent amount of rainfall, there are many buildings experiencing water ingress. Rooftops, basements, lift pits and underground car parks are particularly vulnerable during and after heavy rainfall or prolonged periods of rain.

When the soil gets saturated with rainwater, cold joints, floor/wall joints, cracks in concrete and masonry basement walls or floors can turn into active water leaks.

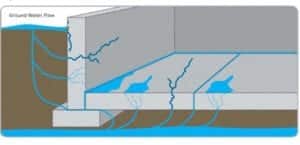

The hydrostatic pressure from the rising water table and the lateral pressure from saturated soil are pushing the excess water into basement slabs, foundations and retaining walls making them susceptible to water ingress through cracks, porous building materials, holes, joints and/or inadequate waterproofing.

Typical water ingress points in basements.

Some common signs of water ingress:

- Damp patches on plaster walls

- Damp skirting boards

- Discolouration and black spots of mould on inside walls, near skirting board

- Peeling paintwork

- Blistered (hollow sounding) plaster

- A damp and musty odour

Mould or damp patches are not always visible and you may have hidden mould or damp if:

- There is a mouldy/earthy odour

- There is regular condensation indoors

- The room feels regularly humid

This room (pictured) is situated in a partially below ground area of the house and our client had identified that they were experiencing water ingress in some areas of the room. Our Waterstop Solutions inspector observed that there were signs of water ingress through the floor/wall joint and the walls.

Watch the progress of how we made this basement waterproof in this video:

We rectified the leaks as outlined below:

Scope

- Surface preparation: Remove existing bitumen waterproofing membrane.

- Perform leak sealing injection into floor/wall joint.

- Install a reverse side cementitious waterproofing membrane to the walls in multiple layers on top of a primer system.

- Prime and seal the vertical gap in the wall with mastic joint sealant and apply membrane NSM100+.

- Surface preparation of the walls: After the wall sheeting was removed to provide access, our leak sealing specialist mechanically removed the existing bitumen waterproofing membrane back to the substrate. Any holes and deep grout lines were filled with a suitable concrete repair mortar.

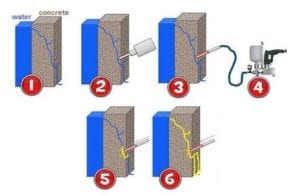

- Leak sealing injection of floor/wall joint: Our leak sealing specialist intersected the joint at intervals and injected a flexible polyurethane at high pressure into the joint. After allowing the polyurethane to react and bind with any water present in the joint and surrounding concrete to form a flexible seal, the injection ports were removed, and holes filled with a suitable concrete repair material.

Image: Example of leak sealing injection with polyurethane resin into a concrete wall.

The leak sealing process, or polyurethane injection, involves the high-pressure injection of flexible water-reactive polyurethane (resin) into targeted areas to form a durable seal. This system is ideal where a long-lasting waterproof seal is required to stop the passage of water or other liquids through gaps, cracks, joints, and penetrations – typically in concrete and masonry constructions.

It is a highly specialised process, requiring the skills of experienced operators. At Waterstop Solutions, our technicians perform polyurethane injection works frequently. They receive ongoing training from industry leaders which equips our technicians with expert skills and knowledge.

We use the best Polyurethane (PU) product available as our primary injection resin. This resin offers superior performance. Its main features include permanent flexibility; very low shrinkage; water potable; low viscosity; and a hydrophilic reaction – it is the same product that is pre-approved by major traffic authorities around the world for major infrastructure assets.

This system can be installed in any weather – in fact, the wetter the better, as it reacts with water right before your eyes. In dry weather, flooding the source of water entry (where possible) may have a similar effect.

Waterstop Solutions’ proprietary injection system exceeds the highest injection process and safety standards in Australia and internationally throughout Europe and the USA.

We continually review and reassess the method, always striving to hone and improve our systems. Our proprietary leak sealing system forms a long-lasting flexible seal against water ingress which also withstands normal building movement between construction elements and details.

- Walls: After the leak sealing injection of the floor/wall joint was completed, a primer was applied to the wall before the reverse side cementitious waterproofing membrane (NSM100+) was installed in multiple layers.

Our waterproof membrane (NSM 100+) is a two-component acrylic modified cementitious coating that is flexible so that it can handle a small amount of movement.

This membrane is a hardwearing, seamless waterproofing membrane for effective concrete protection. It also provides an effective barrier to waterborne salts and atmospheric gases.

The NSM 100+ system is breathable. Whilst repelling water, it allows moisture to pass through it slowly as a vapour, allowing the substrate to breathe.

It is water-based, so any vapours are non-toxic and ideal for potable water usage and it can be painted over in water-based breathable paints (e.g. low sheen or matt acrylics) and most water-based after-trades such as direct stick, tiles or render.

- Vertical gap: The vertical gap in the wall was primed and a backing rod was inserted, followed by the application of mastic joint sealant to fill and seal the gap. This area of the wall had additional applications of the cementitious membrane NSM100+.

Give us a call to discuss the best protective treatment application for your vertical and horizontal surfaces to help you choose the appropriate product and methods to protect them and how to best prepare the surface before installation for best performance.

If you have any issues with water ingress, rooftop leaks, leaking balcony, leaking basement, cracking concrete slabs, structural cracks, concrete deterioration, spalling concrete, concrete cancer, deteriorated joints, moisture, seepage, efflorescence, rising damp and/or high-flow active leaks in concrete structures, we would be happy to assist you. You are welcome to contact us with any questions that you may have.

Brisbane office: (07) 3205 1899

Email: [email protected]

Sydney office: (02) 9346 8308

Email: [email protected]

Are you interested in finding out more about the various remedial building services we are providing?

Please click on the image below to download Waterstop Solutions Capability Statement

Waterstop Solutions Capability Statement is now available to download as PDF. (The image is clickable and opens up a link to our Capability Statement).

Good maintenance begins with a proactive approach to maintain, keep, preserve and protect a building.

Remember that seepage/water ingress into areas such as balconies, basements, concrete roofs, car parks and retaining walls, should not be ignored – call a remedial waterproofing professional today for an assessment to provide you with the best solution for your situation.

At Waterstop Solutions, we carry out a wide range of remedial works to concrete structures post-construction stage in Brisbane, Gold Coast, Sunshine Coast, Sydney and outlying areas in Queensland and New South Wales.

Equipped with major civil works experience, we can quickly determine the best approach to rectify all seepage and concrete deterioration issues.

It takes licenced remedial waterproofer and leak sealing experts like us at Waterstop Solutions to ensure that the pathways for water to ingress are properly sealed off. A depth of technical knowledge and experience, along with a proud reputation for integrity and reliability, has made Waterstop Solutions the go-to company for many Defect Managers working for major construction companies across Queensland and New South Wales.

We at Waterstop Solutions have the technical and practical expertise to diagnose the source of the leak and will provide you with our recommended solution to achieving an effective, high-quality, long-lasting repair to stop the water ingress with minimal disruption

We believe in and are committed to always delivering high-quality solutions by utilising the right products and techniques for each specific project combined with our industry-leading know-how on tap. We have a large talent pool of specialist leak sealing and concrete repair technicians with Certificate III in construction waterproofing in Queensland and New South Wales that are extensively trained in our systems and project execution methods.

The leadership positions on every Waterstop Solutions project are operated by highly qualified, certified and experienced industry professionals. Our in-house skills and expertise gained from more than 60 years of industry experience provide a full range of high-quality remedial waterproofing and concrete repair works to commercial buildings, civil infrastructures, industrial sites and residential properties. From waterproofing diagnostics, preventative and remediation solutions – All of our waterproofing solutions are quality guaranteed.