23 Feb Concrete slab edge repair and leak sealing works

Subscribe to our newsletter

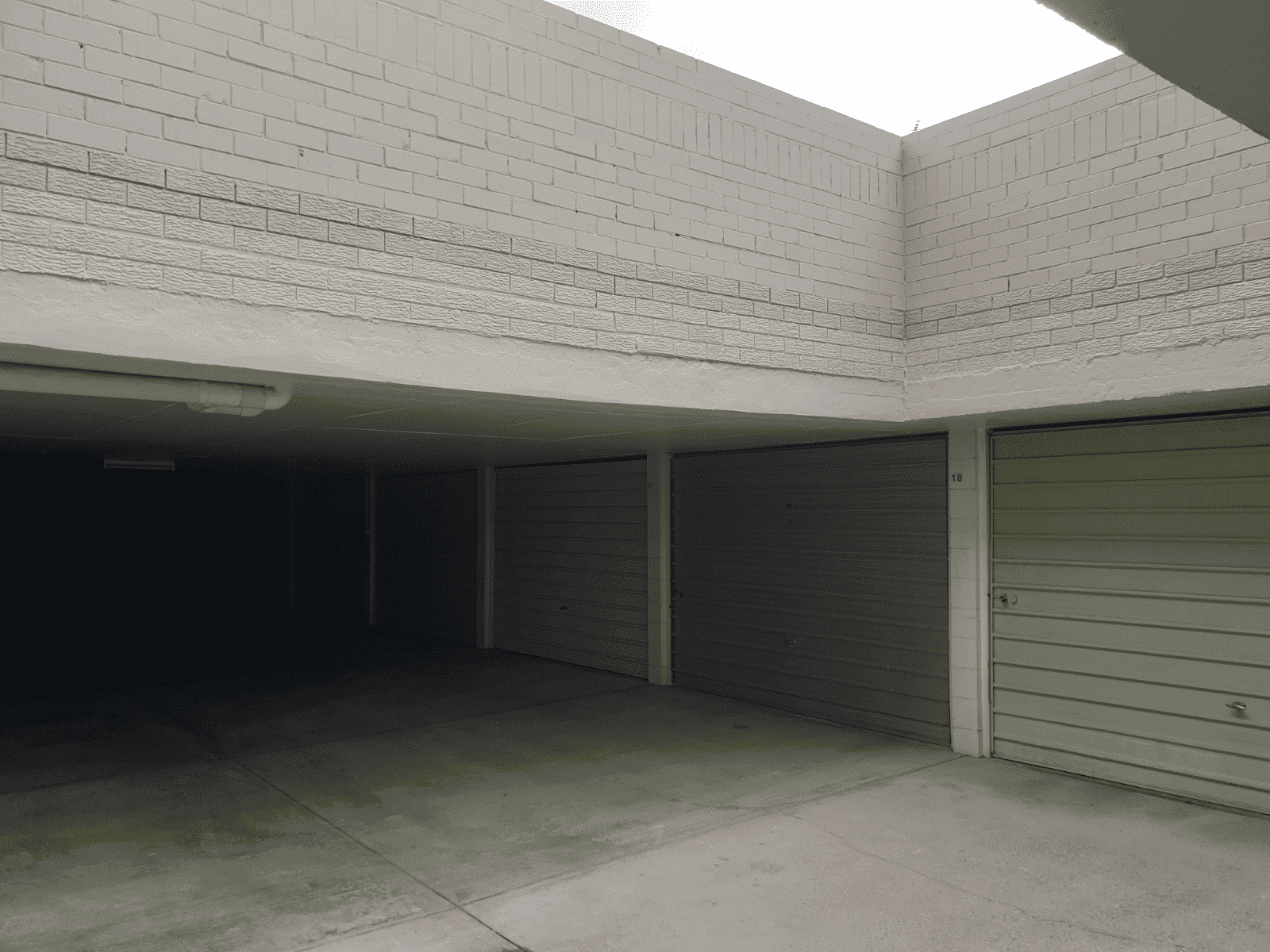

This is a job that shows some of our diversity in waterproofing and concrete defects repairs; Spalling concrete repair of a slab edge and leak sealing injections of a wall-floor joint, pipe penetrations, a slab crack and a cold joint over a dividing wall in a Brisbane garage.

This slideshow presents some examples of the steps of the works carried out.

Background story:

The body corporate management of this property contacted Waterstop Solutions to inspect and remediate a concrete slab edge with signs of spalling concrete*. Based on our inspector’s assessment, the spalling concrete along the slab edge is caused by water leaking through the floor/wall joint from the lawn and planter box area directly above the slab.

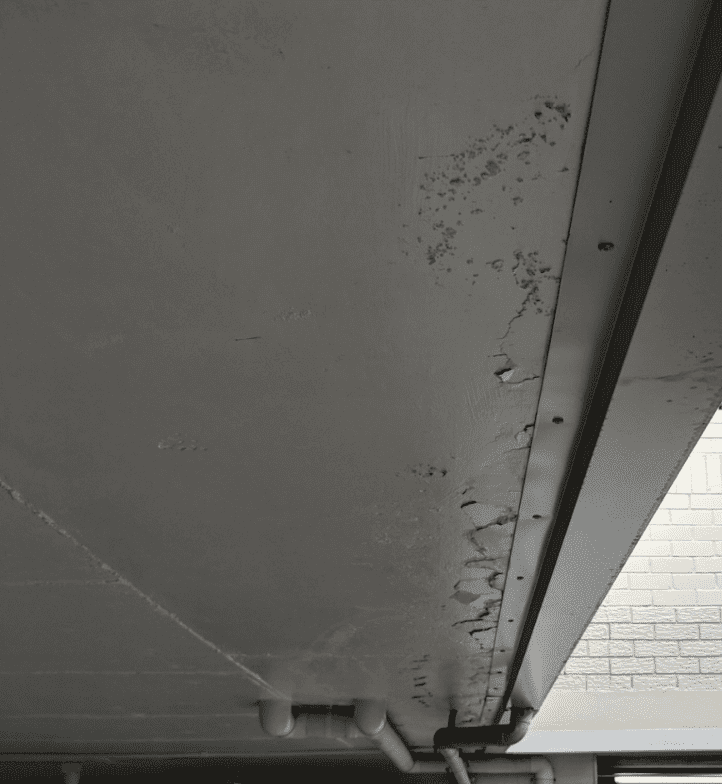

During the inspection, our inspector noted that guttering was installed right underneath the slab edge to help divert the water. Unfortunately, the guttering further exacerbated the concrete spalling. The guttering was in close contact with the concrete slab, creating a high humidity environment. As water continued to soak the concrete, it caused the supporting internal reinforcement steel to rust and expand, which in turn lead to spalling concrete/concrete cancer.

We also identified that there were two leaking pipe penetrations, a concrete crack and a leaking cold joint over a divining wall in the garage. All of which, we recommended sealing by injecting hydrophilic polyurethane resin under high pressure into targeted areas. Our injection process creates a continuous three-dimensional flexible seal buried in the concrete using a combination of proprietary methods, developed and honed over thousands of projects.

To repair the spalling concrete, the leaking pipe penetrations, cold joint and concrete cracks, we recommended the following to rectify the concrete defects and water ingress:

Scope

- Remove render to expose the floor/wall joint.

- Perform leak sealing injection of floor/wall joint with hydrophilic polyurethane resin.

- Remove guttering along the slab edge.

- Perform concrete repairs along both sides of the slab edge.

- Replace damaged reinforcement steel (reo/rebar).

- Apply a rust inhibitor and primer is to the steel and exposed concrete.

- Install formwork to support the installation of the repair mortar.

- Install the shrinkage compensated structural mortar to the repair zone.

- Perform leak sealing injection of 2 pipe penetrations and 1 concrete crack with hydrophilic polyurethane resin.

- Perform leak sealing injection of cold joint over dividing wall in the garage with hydrophilic polyurethane resin.

The guttering was not required to be replaced as the leak sealing injection has successfully stopped the water ingress. We repainted and cleaned up the job site.

* Spalling is the deterioration of steel-reinforced concrete and is generally characterised by the appearance of cracks and rust. In severe cases, concrete sections completely break away from the steel reinforcing, thereby exposing the steel reinforcing to the elements. Spalling is often referred to as “concrete cancer”, as (like cancer) the problem is not obvious initially, and as the problem advances, the treatment becomes increasingly difficult and costly.

Signs to look out for in concrete and cement render:

- Flaking, crumbling, spalling, expanding concrete

- Rust Stains leaking out of the concrete

- Bubbling, blistering, plating of concrete render

- Leaks in overhead concrete surfaces

- Rusting and exposed reinforcement pushing concrete so that it cracks and becomes loose

The challenge is that the small signs of concrete cancer/spalling concrete one can see often hide more extensive damage than is apparent on the surface.

Gutter and signs of spalling concrete slab edge

Gutter removed and excavation of spalling concrete started

Risk of concrete cancer

Several factors predetermine the risk of concrete cancer, including proximity to the coastline and a built-up environment; the degree of concrete cover to steel reinforcing; the presence of differential metals; the quality and density of coating systems; inadequate waterproofing; building defects such as cracking; inefficient joint and penetration detailing and the level of preventative maintenance.

Some of the most common locations one can find corrosion of reinforcement steel are in columns and beams with the primary cause being lack of concrete cover to protect the steel and/or poor-quality concrete. Other common areas of water-driven concrete cancer are basements, underground car parks, flat concrete rooftops and balconies.

Corrosion of reinforcing steel or other embedded metals is by far the leading cause of premature ageing, deterioration and durability issues in concrete. Concrete cancer can happen in many areas of a concrete structure, so carrying out regular inspections is important. Identifying tell-tale signs at an early stage means that issues can be remedied before they become serious and start affecting the structural integrity of the building.

To help prevent spalling from occurring in cured, new concrete, cracks and holes should be adequately sealed as soon as possible. A crack that is identified as small and fine, can be repaired by v-cutting with a concrete crack chaser and filled with suitable material.

Depending on the depth and/or width of the crack, certain concrete cracks may best be repaired by targeted injection of appropriate material (i.e. suitable epoxy or polyurethane resins) tailored to the individual crack’s diagnosis – followed by a suitable protective concrete coating.

A protective coating, a penetrative concrete sealer or a waterproof membrane will provide a barrier against moisture, salts and chemical attacks. This will help improve the durability of the surface and prevent a corrosive environment from developing around the reinforcement.

The goal is to ensure that the long-term integrity of the concrete elements is not compromised.

When spalling concrete/concrete cancer has been repaired, it is important to take preventative steps to ward off a recurrence. We recommend implementing a maintenance program tailored for the environment the building is subjected to including dedicated inspections. Regular maintenance checks will help identify any problems in the early stages for repairs, which again will help enhance the service life and reduce the life cycle cost of concrete structures.

Give us a call to discuss the best protective treatment application for your vertical and horizontal surfaces to help you choose the appropriate product and methods to protect them and how to best prepare the surface before installation for best performance.

If you have any issues with water ingress, rooftop leaks, leaking balcony, leaking basement, wet lift pit, cracking concrete slabs, structural cracks, concrete deterioration, spalling concrete, concrete cancer, deteriorated joints, moisture, seepage, efflorescence, rising damp and/or high-flow active leaks in concrete structures, we would be happy to assist you. You are welcome to contact us with any questions that you may have.

Waterstop Solutions teams are available for all your concrete repair and remedial waterproofing needs in Brisbane, Gold Coast, Sunshine Coast and Sydney.

Brisbane office: (07) 3205 1899

Email: [email protected]

Sydney office: (02) 9346 8308

Email: [email protected]

Are you interested in finding out more about the various remedial building services we are providing?

Please click on the image below to download Waterstop Solutions Capability Statement

Waterstop Solutions Capability Statement is now available to download as PDF. (The image is clickable and opens up a link to our Capability Statement).

Good maintenance begins with a proactive approach to maintain, keep, preserve and protect a building.

Remember that seepage/water ingress into areas such as balconies, basements, concrete roofs, car parks and retaining walls, should not be ignored – call a remedial waterproofing professional today for an assessment to provide you with the best solution for your situation.

At Waterstop Solutions, we carry out a wide range of remedial works to concrete structures post-construction stage in Brisbane, Gold Coast, Sunshine Coast, Sydney and outlying areas in Queensland and New South Wales.

Equipped with major civil works experience, we can quickly determine the best approach to rectify all seepage and concrete deterioration issues.

It takes licenced remedial waterproofer and leak sealing experts like us at Waterstop Solutions to ensure that the pathways for water to ingress are properly sealed off. A depth of technical knowledge and experience, along with a proud reputation for integrity and reliability, has made Waterstop Solutions the go-to company for many Defect Managers working for major construction companies across Queensland and New South Wales.

We at Waterstop Solutions have the technical and practical expertise to diagnose the source of the leak and will provide you with our recommended solution to achieving an effective, high-quality, long-lasting repair to stop the water ingress with minimal disruption

We believe in and are committed to always delivering high-quality solutions by utilising the right products and techniques for each specific project combined with our industry-leading know-how on tap. We have a large talent pool of specialist leak sealing and concrete repair technicians with Certificate III in construction waterproofing in Queensland and New South Wales that are extensively trained in our systems and project execution methods.

The leadership positions on every Waterstop Solutions project are operated by highly qualified, certified and experienced industry professionals. Our in-house skills and expertise gained from more than 60 years of industry experience provide a full range of high-quality remedial waterproofing and concrete repair works to commercial buildings, civil infrastructures, industrial sites and residential properties. From waterproofing diagnostics, preventative and remediation solutions – All of our waterproofing solutions are quality guaranteed.